The present consumer goods market is quite dynamic and the packaging of goods has assumed a greater role than simply holding the products to critical contribution in the sphere of safety, convenience, sustainability and brand perception.

Spout pouches are also emerging to be a favorite when it comes to food and liquid packaging that is utilized in food and liquid items, such as juices and sauces, condiments and nutritional liquids. But as the demand grows, there is one large question to ask and that is, are the spout pouches safe with food and liquid products?

To provide the resounding yes to that, it is critical to take into concern the design parameters of these pouches, the materials used and the possibility to provide the integrity of the product in the context of product supply chain.

What Makes Spout Pouches Suitable for Food and Liquids?

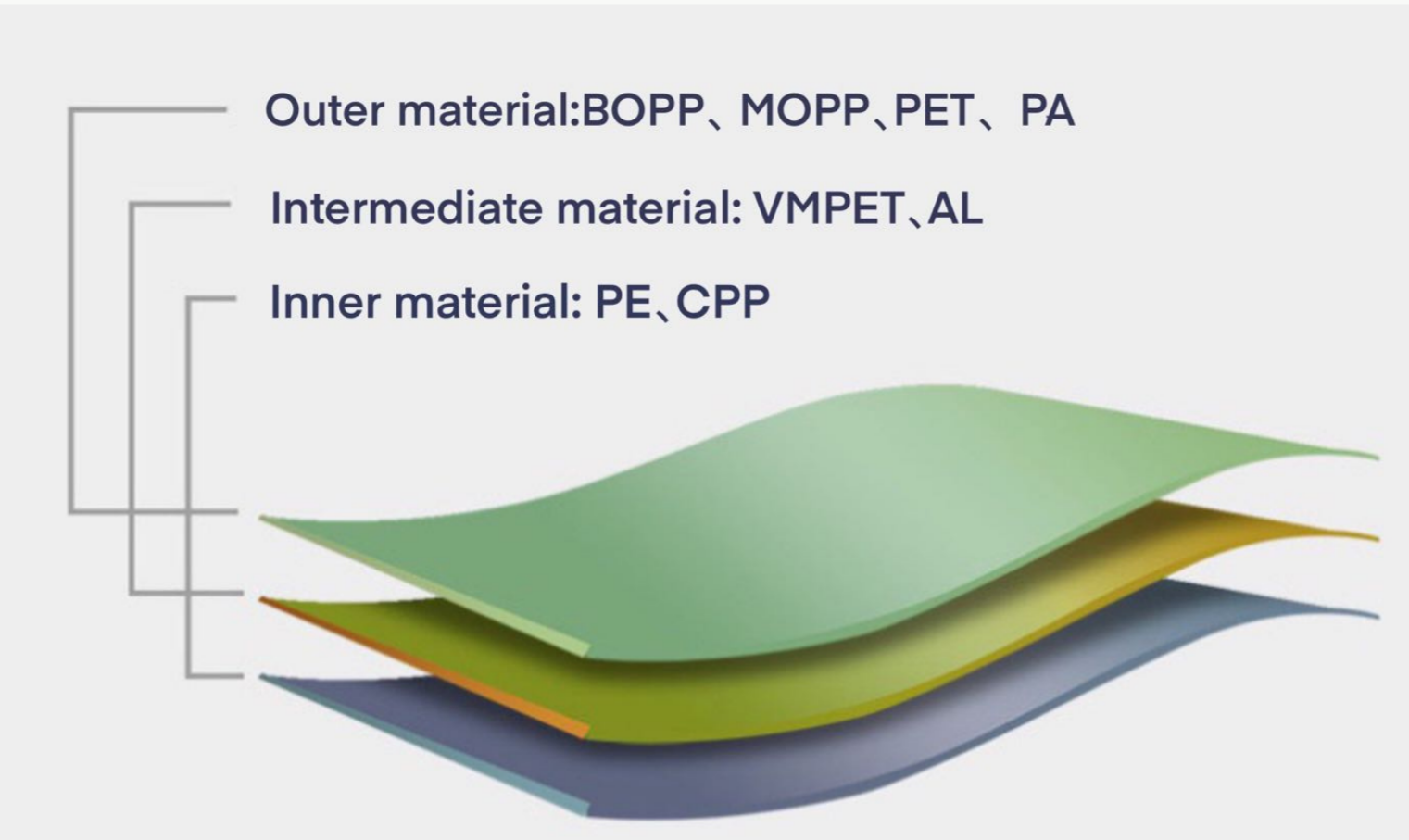

The spout pouches are structured in terms of multi-layered laminated films that comprise of strength, barrier protection and food contact surfaces.

Multi-layer composite materials are normally used to make spout pouches and offer varying functional properties.

1. Common composite structures include:

PET/AL/PE: This is the most popular 3-layered type of composite structure, which is applicable to liquids, juices, and beverages of the same nature. PET layer is strong and easy to print, aluminum foil layer is good in barrier properties and PE layer is good in sealing and leak resistance.

PET/NY/PE: It is a structure applied in products with greater pressure resistance or sealing strength. It has the inclusion of nylon layer that gives it improved mechanical strength, which makes it apt to other product types such as sauces, detergents, etc.

PA/AL/PE: nylon (PA) layer has greater temperature and puncture resistance, thus it can be used in high temperature treatments and high-end products, like sauces and liquid foods.

Single-Layer Materials

PE (Polyethylene): It is useable with light products such as powders, granules and grains. It is with high sealing properties, good moisture resistant properties yet it has poor barrier properties.

PP (Polypropylene): It is majorly applicable in dry products, and it is more rigid and transparent, which makes it the best to be applied in packaging that demands high transparency, e.g., candies and nuts.

3. Eco-friendly Materials

As the trend of environmental goes, increased spout pouches are manufactured using recyclable or biodegradable material:

Biodegradable Materials: This type of material includes PLA (Polylactic Acid), polybutylene Succinate, which are perfect materials when it comes to food and beverage packaging. These materials break down to eco-friendly materials after some time lowering the environmental impact.

Paper-Plastic Composites: These are applied to some foods (such as dairy products) and household chemicals. The incorporation of paper is more printable and greener.

The inner part, that is typically PE, is selected because of its excellent heat-sealing properties and chemical resistance but outer layers like PET provide structural strength and appearance. A combination of these layers when laminated appropriately forms a system of barrier that blocks the external environmental factors to food and liquid products thus preserving quality and further enhancing shelf life.

Its safety advantage is that it has resealable spout cap which has helped the consumers open, dispense and reclose the pouch without exposing the contents to unnecessary contamination. The spills are avoided and there is less wastage of goods especially liquid and semi-liquid goods such as sauces, juices and puree.

Barrier Protection and Shelf Life: Keeping Contents Fresh and Safe

The importance of food safety is not just about the ways of prevention of food contamination, but also to freshness, taste, and nutrition of the product during the lifecycle.

It is in this regard that multi-layer structures used in spout pouches are fabricated. To take an example, the incorporation of such materials as EVOH can play a big role in the development of resistance against oxygen permeation which is among the factors that determine the preservation of the perishable products.

The moisture is retained in the high-barrier pouches and light and gases transfer-factors that could contribute to the spoilage. In practice, this comes in handy in the lengthening of shelf life without either the application of any preservatives or overly harsh treatment. It is one of the reasons why spout pouches take place in such segments as juice, dairy substitutes, sauces and purees.

It is also necessary to note that though it is stated that spout pouches are effective with most products, there are situations when it has failed to work on highly acidic carbonated or volatile liquids, which may require special films to be used or engineering controls to be implemented.

Manufacturing Quality and Food Safety Compliance, and Real-World Use Cases

Besides material science, manufacturing quality and regulations are also relevant in the spout pouch safety. The suppliers of food products of reputable suppliers are compliant to the requirements of food safety such as the FDA or EU food contact regulations and conduct integrity tests, such as seal strength, burst pressure, material migration tests.

Spout pouches have been found to be dependable and have been adopted by the consumers in the real world setting in the normal consumption of ready to drink beverages and baby food and foodstuff preparatory products used in a food preparatory setting, hydration goods and so on. The resealable design, regulated dispensing and clean sealing is all changed to the safe handling directing towards the production lines up to the kitchen countertops.

Of course, storage and handling is also required. Spout pouches, similar to other types of packaging, should be resistant to high temperatures, sharp edges, and prolonged UV light, or it will ruin the packaging and products themselves.

Conclusion Spout pouches are a safe and viable way of packing a wide range of food and liquids when packaged properly they must be of the right material and should be tested properly to the standards demanded and they should also be filled properly. They provide an amalgamation of functionality and user experience and high-protection barrier levels making it an intelligent choice in the list of products that should be convenient, secure, and sustainable in the packaging by modern brands.